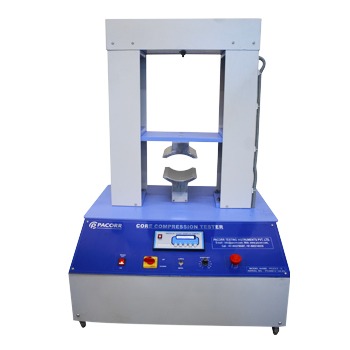

The Core Compression Tester from Pacorr embodies an indispensable asset for ensuring the quality and integrity of cylindrical structures under compressive forces, pivotal for industries such as paper, packaging, and textiles. Its superior technology, including precision load sensors and advanced microprocessor controls, facilitates accurate measurements of core crushing strength, critical for assessing the durability and performance of products under real-world conditions. The integration of features like auto calibration and safety switches further enhances the tester’s reliability and user safety, making it an invaluable tool for quality control professionals. By simulating the exact stress conditions encountered during storage, transport, or use, Pacorr’s Core Compression Tester provides a clear insight into the product’s performance, aiding in the optimization of manufacturing processes and material quality. This rigorous testing ensures that only the highest quality products reach the market, thereby maintaining production efficiency and customer satisfaction.

The Core Compression Tester is a pivotal instrument in quality assurance technologies for industries reliant on cylindrical packaging forms like cones or cylinders, especially within the yarn and tissue paper sectors. This machine is essential for assessing the vertical load-bearing capacity of these materials before yielding to crushing pressures, ensuring their durability and reliability during production and usage phases.

The significance of employing such a device lies in its ability to simulate real-world stress conditions that cylindrical structures, such as paper cones used in the yarn industry or tissue paper cylinders, would encounter. By assessing these materials’ core crushing strength, manufacturers can predict product performance and identify potential failure points, thereby optimizing the quality and durability of their output.

Moreover, Pacorr’s commitment to quality and excellence is evidenced not only through their product offerings but also by their esteemed clientele, including major corporations like Unicharm, Nestle, Philips, Tupperware, and Honda Car India Limited. These collaborations underscore Pacorr’s capability to meet diverse industry needs and reinforce their position as a leader in the quality testing equipment market.

thg

test

Box Compression Tester is a machine used to measure the strength and durability of corrugated boxes and other packaging materials. It applies compressive force on the box or package until it collapses or reaches a specified limit. The amount of force required to compress the package is measured and analyzed to determine its stacking strength and overall integrity. This helps manufacturers and suppliers ensure that their packaging materials can withstand the rigors of transportation and storage, and protect the contents of the package from damage.

We offers Box Compression Tester in different capacities and sizes according to the customer requirements. Customization of the machine is also available on request of the customers.

If your machine is not showing correct results, there is a possibility that your machine needs to be recalibrated. In that case, you can contact our customer support so that they could guide about the recalibration of the machine.

The machines that are manufactured by Pacorr are basically fabricated using the best grade materials and hence require minimal maintenance. For instance, greasing the lead screw, keeping the machine dust free and away from moisture are some of the things that you should do regularly for longer life of the machine.

You can try pressing the TARE button given on the digital display. This will reset the display and you can restart the test. If that does not solve the problem, you can contact our customer support team.

We offer a very comprehensive testing instrument that can be used for testing the strength of the packaging containers. The containers that can be tested Box Compression Tester including cardboard boxes, corrugated boxes and containers.

Pacorr’s Core Compression Tester is a high-precision instrument designed for measuring the crushing strength of cylindrical objects such as paper rolls, cardboard tubes, and other similar materials. It’s crucial for industries that require rigorous quality control of their packaging materials.

The tester applies a controlled vertical force to the material until it collapses. The maximum force applied at the point of failure is recorded, providing an accurate measure of the material’s strength and durability under compressive stress.

This tester is essential for the paper and packaging industries, textile manufacturing, and any sector that uses cylindrical packaging or components. It helps ensure that products can withstand handling, shipping, and storage pressures without failing.

Advanced Electronics: For precise and accurate test results.

Precision Load Sensor: Ensures highly accurate measurements.

Tare and Peak Hold Facility: Useful for resetting measurements and capturing peak force values.

Adjustable Speed Drive: Allows customization of the test speed from 10mm/min to 50mm/min.

Robust Construction: Designed for durability and long-term use in industrial environments.

Consider your specific testing requirements, including the maximum force capacity, the dimensions of the specimens, and any specific industry standards you need to meet. Pacorr offers various models to suit different needs, so reviewing the specifications of each model is recommended.

Yes, it’s an invaluable tool for quality assurance processes, enabling manufacturers to verify that their cylindrical packaging materials meet required strength specifications. This helps in minimizing product damage during shipping and handling.

While designed for ease of use, operators may benefit from an initial training session to familiarize themselves with the machine’s features and functionalities. Pacorr provides comprehensive manuals and customer support for training purposes.

Pacorr recommends regular calibration to ensure ongoing accuracy. The frequency may vary based on usage, but generally, annual calibration is advised or after a significant volume of tests to maintain precision.

P. O. Box 11723- Las Vegas NV 89111

United States of America

Email: [email protected]