Calculating the Coefficient of Friction (COF) for plastic sheets and films quantifies the resistance between two surfaces as they slide against each other. When it comes to packaging films, functionality and performance are essential. The coefficient of friction (COF) holds a crucial role in predicting the usability of the material. It is a critical factor in applications ranging from packaging to industrial processes. For manufacturers in this field, understanding and controlling COF is essential. Let’s explore the significance of COF testing and the role of the right testing instrument from reputed suppliers to ensure accuracy.

Understanding the Coefficient of Friction Testing

The coefficient of friction testing evaluates the interaction between two materials in contact by measuring their resistance to sliding motion. More importantly,

in plastic films and sheet manufacturing. The COF plays a key role in winding, packaging, printing, etc. Excessive COF can lead to difficulties in processing, while inadequate COF can result in instability during storage and transportation. Therefore testing allows manufacturers to optimize material choices, processing conditions and evaluate end-product performance.

The Role of the Right Testing Instrument

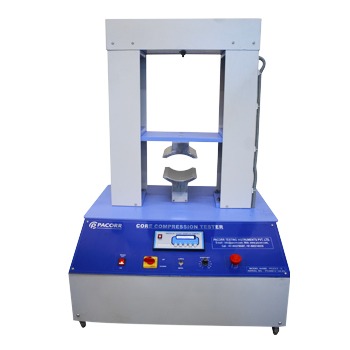

When it comes to choosing the right COF testing instrument, it is vital to look for instruments that offer convenient testing along with accurate and meaningful results. Reputed suppliers like Pacorr offer advanced COF testers equipped with cutting-edge technology that ensures precision, reliability and global compliance. The following pointers can help you find the right instrument for the coefficient of friction testing.

- Reliable testing instruments minimize errors and inconsistencies. Therefore it is crucial to consider the testing process and features before purchasing.

- Consistent and reproducible results are imperative to eliminating variations arising from manual error or testing techniques.

- Opt for testing instruments that provide swift and efficient testing procedures. This helps save time and resources without compromising accuracy.

- Digital COF testers provide comprehensive data analysis and reporting capabilities with a record of up to 9 test results. This enables manufacturers to identify trends, correlations, and areas for improvement.

Globally Accepted Test Results:

The manufacturing segment demands adherence to globally accepted testing standards. Reputed suppliers like Pacorr ensure that their COF testing instrument complies with international standards such as ASTM and ISO. This helps ensure test results’ reliability and facilitates communication across the industry.

Elevating Performance With COF Tester By Pacorr

Understanding and controlling COF is strategically imperative to ensure the applications and safety of the end product. The right COF testing instrument helps ensure accuracy, adherence to industry standards, and insights results that facilitate product optimization. As manufacturers across the globe strive for enhanced product performance integrating specialized testing instruments like COF tester by Pacorr can empower them with the edge required to gain a position at the forefront.

FAQ – Frequently Asked Questions

- What materials can be tested for COF?

The COF testing is relevant for a wide range of materials, including plastic films, sheets, lubricants, papers, textiles, and more.

- How does COF affect packaging applications?

In packaging, COF determines how the interaction of packages and conveyor belts. It is helpful to determine how films can be layered during winding and how packages are stacked during transportation.

- Can COF be too low?

Yes, excessively low COF often result in instability during processing and transportation, leading to potential difficulties in unwinding and slipping.