PET bottles have consistently been preferable for preserving and delivering a wide range of liquids, from water, medicines, beverages, oils, detergents, etc. The demand for durable PET bottles and reliable packaging is growing steadily. Manufacturers are increasingly focusing on ensuring the strength and integrity of PET bottles. Top load testing is emerging to be a cost-effective solution to check the integrity of PET bottles. This testing process is vital to gain a comprehensive insight into the bottle’s ability to withstand external pressures. Let’s delve into the importance of top load testing, the role of the right testing instruments, and how reputed suppliers like Pacorr can ensure accuracy and globally accepted test results.

Understanding Top Load Testing

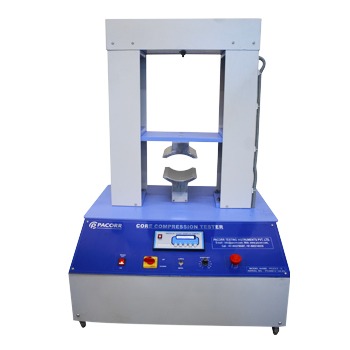

Top load testing involves evaluating the PET bottle’s resistance to vertical pressures. This testing process mimics real-world scenarios wherein the bottles are stacked post-production, transported, or stored. This makes vertical resistance an essential quality control measure. The top load tester is the right instrument that allows manufacturers to test the performance of PET bottles conveniently. It works by subjecting bottles to controlled pressure. Manufacturers can identify weaknesses, design flaws, or inconsistencies in the manufacturing process. This helps ensure that bottles of superior strength make their way into the market, enhancing consumer satisfaction and brand reputation.

The Role of the Right Testing Instrument

Accurate top-load testing primarily depends on the selection of the right testing instrument. Reputed suppliers like Pacorr offer advanced top load testers equipped with cutting-edge technology that guarantees precise and reliable results. Their microprocessor-based tabletop model provides high-level precision along with protection against overload. Following are a few of the benefits of choosing the right instrument for the testing process:

- Accuracy: A reputable testing instrument ensures accurate measurements, minimizing errors that might arise from manual testing methods. The top load tester by Pacorr is equipped with a variable frequency drive for making informed decisions about bottle strength.

- Consistency: Automated testing instruments deliver consistent results, eliminating variations due to human error or inconsistencies in manual testing techniques.

- Speed: Automated testing instruments provide efficient testing procedures, accelerating the quality control process and enabling manufacturers to meet production deadlines without compromising accuracy.

- Data Insights: Modern testing instruments offer detailed data insights and reporting capabilities. The top load tester by Pacorr can automatically record Peak load value trends to understand potential areas of improvement in bottle design or manufacturing processes.

Globally Accepted Test Results

In an increasingly interconnected world, consumers have a diverse range of options in order to choose the right product. Therefore adhering to globally accepted testing standards is crucial for manufacturers to gain distributors’ and consumer’s trust. Reputed suppliers like Pacorr ensures that their equipment complies with international testing standards such as ASTM D2659 and ISO 12048. This ensures the credibility of the test results and facilitates seamless communication and collaboration within the industry.

Advancing Packaging Excellence With Pacorr

The strength and durability of PET bottles play a key role in consumer trust and brand success. Top load testing is a fundamental quality control measure that cannot be overlooked. Manufacturers can ensure accuracy, consistency, and globally accepted standards by choosing the right testing instrument. As the demand for reliable products continues to rise, top load testing is crucial to delivering PET bottles that meet the highest standards of excellence and durability.